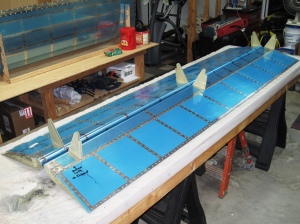

Now that the Fuel Tank Sealant has had time to cure along the Trailing Edges of the Flaps, I continued by removing all the clecoes along the Trailing Edge and cleaned out the holes with a drill bit. Next I final-drilled #33 the Bottom Skin and Main Ribs so that I could blind rivet them together using the MK-319-BS pull rivets. I also riveted each end of the Flap using my hand squeezer and AN426AD3-3.5 solid rivets.

Finally I back riveted the Trailing Edge just like I had done before, by first setting the tool parallel to the surface of the back riveting plate and rotating the tool to be parallel with the surface of the rudder as I riveted. I set all the AN426AD3-3.5 rivets half way, then came back with my mushroom set and riveted the shop head flush with the Bottom Skin.

Now just a few more steps before I call it a night. First I pressed a Bushing (1/4X3/8X.25) into the flap attach hole on all six of the Flap Hinge Brackets (W-1025A). Next I attached the Rod End (CM-4M) to the Flap’s inboard end with the bolt (AN4-11A) and washers (AN960-416 & -416L) called for on the drawing. Lastly the torque range for an AN4 bolt is 50-70 in-lbs.; therefore I torqued the bolts to 60 in-lbs.